PET

Polyethylene terefthalate (wani lokacin an rubuta poly (ethylene terephthalate)), wanda aka shafe tsawon lokaci PET, Pete, ko PETP wanda aka saba aiki dashi ko PET-P, shine mafi yawan jama'a thermoplastik polymer guduro na polyester iyali kuma ana amfani dashi a cikin zaruruwa don sutura, ganga don taya da abinci, thermoforming na masana'anta, kuma a hade tare da fiber gilashi don resins injin.

Hakanan ana iya kiransa da sunan alamar Dacron; a Burtaniya, Terylene; ko, a cikin Rasha da tsohuwar Tarayyar Soviet, Lavsan.

Mafi yawan abin da ake samarwa na PET a duniya shine na zaren roba (sama da kashi 60%), tare da samar da kwalba kimanin 30% na bukatar duniya. Dangane da aikace-aikacen yadi, ana kiran PET da suna na gama gari, polyester, alhãli kuwa acronym PET ana amfani dashi gabaɗaya dangane da kicin. Polyester ya tashi kusan kashi 18% na abubuwan da ake samarwa na polymer a duniya kuma shine na huɗu da aka fi samarwa polymer; polyethylene(PE), polypropylene (PP) da polyvinylchloride (PVC) sune farko, na biyu da na uku, bi da bi.

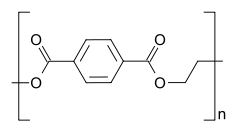

PET ta ƙunshi polymerized raka'a na monomer ethylene terephthalate, tare da maimaitawa (C10H8O4) raka'a. PET yawanci ana sake jujjuya shi, kuma yana da lamba 1 a matsayin alamar sake sarrafawa.

Ya danganta da sarrafawa da tarihin yanayin zafi, polyethylene terephthalate na iya kasancewa duka a matsayin amorphous (m) kuma a matsayin Semi-crystalline polymer. Theaƙarin semicrystalline na iya bayyana a bayyane (girman kwaya <500 nm) ko opaque da fari (girman kwaya har zuwa mican micrometers) ya danganta da tsarin ƙirarsa da girman kwayar. Mai tsara ta bis (2-hydroxyethyl) terefta za a iya hada shi ta esterification dauki tsakanin Sankaracic acid da kuma sinadarin glycol tare da ruwa a matsayin byproduct, ko ta fassarar dauki tsakanin sinadarin glycol da kuma karafarin rage tare da methanol a matsayin byproduct. Polymerization ne ta hanyar a polycondensation dauki na monomers (an yi shi nan da nan bayan fashewar / transesterification) tare da ruwa kamar yadda ake haɓaka shi.

| names | |

|---|---|

| IUPAC sunan

Nau'in (ethyl benzene-1,4-dicarboxylate)

|

|

| Alamomin | |

| 25038-59-9 |

|

| gajartatattun | PET, PITA |

| Properties | |

| (C10H8O4)n | |

| Taro na Molar | m |

| yawa | 1.38 g / cm3 (20 ° C), amorphous: 1.370 g / cm3, guda crystal: 1.455 g / cm3 |

| narkewa batu | > 250 ° C, 260 ° C |

| tafasar batu | > 350 ° C (bazu) |

| kusan insolubleble | |

| Ƙararrawar ƙararrawa | 0.15 zuwa 0.24 W m-1 K-1 |

|

Fassara nuni(nD)

|

1.57-1.58, 1.5750 |

| AikinAmurka | |

| 1.0 kJ / (kilogiram · K) | |

| Abubuwan haɗin gwiwa | |

|

related Masu adadi

|

Terephthalic acid Gilin glycol |

|

Sai dai in an lura in ba haka ba, ana bayar da bayanai don kayan a cikinsu daidaitaccen jihar (a 25 ° C [77 ° F], 100 kPa).

|

|

amfani

Saboda PET kyakkyawan ruwa ne da kayan hana ruwa, ana amfani da kwalaben filastik waɗanda aka yi daga PET don abubuwan sha masu taushi (duba carbonation). Don takamaiman kwalabe na musamman, irin waɗanda aka tsara don kariyar giya, PET sandwiches ƙarin polyvinyl barasa (PVOH) don ƙara rage ƙarfin oxygen.

PETRID ta hanyar Biafara fim (wanda galibi ɗayan sunan kasuwancinsa ya san shi, "Mylar") ana iya haskaka shi ta hanyar fitar da wani ƙaramin fim na ƙarfe akan shi don rage tasirinsa, da kuma sanya shi yin juyi da juzu'i (MPET). Waɗannan kaddarorin suna da amfani a aikace-aikace da yawa, gami da abinci mai sauƙin kai marufi da kuma rufin zafi. Duba: “bargo“. Saboda tsananin ƙarfin inji, ana amfani da fim ɗin PET sau da yawa a aikace-aikacen tef, kamar mai ɗauke da tef na maganadisu ko goyan baya don kaset ɗin adon mai matse lamba.

Rashin daidaituwa PET sheet na iya zama zazzana don yin kwastomomin kwanduna da fenti. Idan aka yi amfani da PET na crystallizable, ana iya amfani da trays ɗin don abincin daskararre, tun da yake suna iya tsayayya da daskarewa da yanayin dumama. Kamar yadda aka saba da ampophous PET, wanda yake amintacce ne, PET ko kuma CPET mai ban sha'awa shine mafi launin baki.

Lokacin da aka cika gilashin gilashi ko zaruruwa, ya zama ya fi ƙarfinta kuma zai dawwama.

Hakanan ana amfani da PET a matsayin mai canzawa a cikin fim ɗin bakin ciki na sel.

Terylene kuma an jefa shi a cikin igiya mai sautin kararrawa don taimakawa hana ci gaba da igiyoyi yayin da suke ratsa rufin.

Tarihi

PET an mallake shi a cikin 1941 daga John Rex Whinfield, James Tennant Dickson da mai ba su aikinsu icoungiyar tersungiyar Masu bugun Calico ta Manchester, Ingila. EI DuPont de Nemours a Delaware, Amurka, ya fara amfani da alamar kasuwanci ta Mylar a watan Yunin 1951 kuma ya sami rajista a cikin 1952. Har yanzu shine sanannen sunan da ake amfani da shi don fim ɗin polyester. Wanda ke mallakar alamar kasuwanci a yanzu shine DuPont Teijin Films US, haɗin gwiwa tare da wani kamfanin Japan.

A cikin Tarayyar Soviet, an fara kera PET a cikin dakunan gwaje-gwaje na Cibiyar Magungunan-kwayoyin Halitta na Kwalejin Kimiyya ta USSR a cikin 1949, kuma sunansa "Lavsan" an gaishe shi ne (laоратории Института вysokomolekulyarnыh сондинений АKARNATAKA нукук СССР).

Kwalbar PET ta mallaka a 1973 ta hannun Nathaniel Wyeth.

jiki Properties

PET a cikin yanayinta ba shi da launi, feshin murfin lu'ulu'u. Dangane da yadda ake sarrafa shi, PET na iya zama mai tsaurin kai-tsaye zuwa tsayayye, kuma yana da nauyi sosai. Yana sanya kyakkyawan gas da shingen danshi mai kyau, da kuma kyakkyawan shinge ga shaye shaye (yana buƙatar ƙarin maganin “shamaki”) da sauran ƙarfi. Yana da ƙarfi da tasirin tasiri. PET ya zama fari lokacin da aka fallasa shi da chloroform da kuma wasu wasu sinadarai kamar su toluene.

Kimanin 60% lu'ulu'u shine babban iyaka ga samfuran kasuwanci, banda ƙwayoyin polyester. Za'a iya samar da samfurori masu tsabta ta hanyar kwantar da ƙwayoyin polymer cikin ƙasa Tg zafin zafin gilashi don samar da daskararren amorphous. Kamar gilashi, amorphous PET yakan samar lokacin da ba'a basu kwayoyinsa isasshen lokaci don tsara kansu cikin tsari ba, na lu'ulu'u kamar yadda aka narke narkewar. A cikin zafin jiki a cikin ɗakunan ƙwayoyin suna daskarewa a wurin, amma, idan an mayar da isasshen makamashi a cikin su ta hanyar dumama sama da Tg, suna fara motsawa kuma, suna barin lu'ulu'u su inganta da haɓaka. An san wannan hanya a matsayin kukan-jihar mai karfi.

Lokacin da aka ba shi izinin kwantar da hankali, polymer ɗin da aka yi ƙarfe yana samar da ƙarin kayan lu'ulu'u ne. Wannan kayan yana da zurfafawa dauke da manya da yawa lu'ulu'u lokacin da lu'ulu'u ya fashe daga wani amorphous m, maimakon samar da babban kristal daya. Haske yana buɗewa yayin da yake ƙetare iyaka tsakanin lu'ulu'un lu'ulu'u da yankuna amorphous a tsakaninsu. Wannan watsawa yana nufin cewa PET lu'ulu'u ne fari da fari a mafi yawan lokuta. Zaɓin fiber yana cikin processesan matakai na masana'antu waɗanda ke samar da kusan samfurin kristal guda ɗaya.

Danko ciki

Daya daga cikin mahimman halaye na PET ana kiranta danko na ciki (IV).

Tsarin ciki na ciki na kayan, wanda aka samo ta hanyar zamewa zuwa sifili maida hankali ne kan ɗanɗano dangi zuwa taro wanda aka auna masu yankewa kowace gram (dℓ / g). Tsarin ciki na ciki ya dogara da tsawon sarkar polymer ɗin sa amma ba shi da raka'a saboda kasancewar an ɗora shi zuwa taro ba sifili. Yawan tsinkayen silima yana da mafi kusantuwa tsakanin sarƙoƙi sabili da haka mafi girman danko. Tsawan sarkar matsakaita na wani yanki na resin za'a iya sarrafa shi yayin polycondensation.

Tsarin ganuwa na ciki na PET:

Fiber

- 0.40-0.70 Yarn

- 0.72-0.98 Fasaha, igiyar taya

Fim fim

Kwalban kwalban

- 0.70-0.78 kwalabe ruwa (lebur)

- 0.78-0.85 Carbonated mai laushi mai sha

Monofilament, filastik injin

- 1.00-2.00

Bushewa

PET kenan sankarau, ma'ana yana tsotse ruwa daga kewayensa. Koyaya, lokacin da wannan “damp” ɗin PET ɗin ya ɗumi, ruwan hydrolyzes da PET, yana rage juriya. Sabili da haka, kafin a iya sarrafa resin a cikin injin ƙira, dole ne a bushe. Ana samun bushewa ta hanyar amfani da a mai yankewa ko masu bushewa kafin a ciyar da PET a cikin kayan sarrafawa.

A cikin na'urar bushewa, ana busar da iska mai ɗumi mai zafi a ƙasan hopper mai ɗauke da guduro don ya gudana ta cikin ƙyallen, yana cire danshi a kan hanyarsa. Iska mai dumi mai zafi yana barin saman hopper kuma ana fara gudanar dashi ta bayan mai sanyaya, saboda yana da sauki cire danshi daga iska mai sanyi fiye da iska mai zafi. Sanadin iska mai sanyi mai sanyi yana wucewa ta kan gado mara kyau. Aƙarshe, iska mai sanyayyen bushewa mai barin gado mara ɗaci ana sake ɗumi a cikin hita mai sarrafawa kuma ana mayar dashi ta hanyar hanyoyin ɗaya cikin rufaffiyar madauki. Yawanci, ragowar matakan danshi a cikin gudan dole ne ya zama kasa da kashi 50 a cikin miliyan daya (sassan ruwa a kowane bangare na resin, da nauyi) kafin a sarrafa su. Lokacin zama na bushewa bai kamata ya zama ƙasa da awanni huɗu ba. Wannan saboda bushe kayan cikin ƙasa da awanni 4 zai buƙaci zafin jiki sama da 160 ° C, a wane matakin hydrolysis zai fara a cikin murfin kafin su bushe.

PET kuma za'a iya bushewa a cikin matukan bushewar iska mai bushewa. Matattarar bushewar iska ba ya sake amfani da bushewar iska. An bushe, iska mai matse mai zafi ana watsa ta cikin PET pellets kamar yadda a cikin na'urar bushewa take, sannan aka fito da ita ga sararin samaniya.

Masu Copolymers

Baya ga tsarkakakke (yankance) PET, PET wanda aka gyara ta sarrafin kane yana samuwa.

A wasu halaye, abubuwan da aka gyara na copolymer sun fi dacewa don takamaiman aikace-aikacen. Misali, cyclohexane dimethanol (CHDM) za'a iya ƙara zuwa kashin kashin polymer a madadin sinadarin glycol. Tunda wannan tubalin ginin ya fi girma (6 ƙarin ƙwayoyin carbon) fiye da na ethylene glycol wanda yake maye gurbinsa, bai dace da sarƙoƙin maƙwabta ba kamar yadda ƙungiyar ethylene glycol za ta yi. Wannan yana rikitar da crystallization kuma yana saukar da zafin jiki na narkewar polymer. Gabaɗaya, irin waɗannan PET an san su da PETG ko PET-G (Polyethylene terephthalate glycol-modified; Eastman Chemical, SK Chemicals, da Artenius Italia wasu masana'antun PETG ne). PETG shine keɓaɓɓen thermoplastik ɗin amorphous wanda za'a iya yin allurar allura ko a cire shi da takarda. Yana iya zama launi yayin aiki.

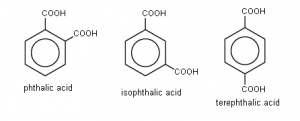

Wata masaniyar zamani ita ce keɓaɓɓen acid, maye gurbin wasu daga cikin 1,4- (misalai) da alaƙa karafarini raka'a. The 1,2- (ortho-) ko 1,3- (makasudin-) haɗin kai yana haifar da kusurwa a sarkar, wanda shima yana rikitar da yawan kuka.

Irin waɗannan masu haɗin gwiwar suna da amfani ga wasu aikace-aikacen ƙira, kamar su zazzana, wanda ake amfani dashi misali don yin kwalin kwalliya ko marfin ruwa daga fim ɗin co-PET, ko amorphous PET sheet (A-PET) ko takardar PETG. A gefe guda, lu'ulu'u yana da mahimmanci a cikin wasu aikace-aikace inda ingantacciyar injiniyan da girma suke da mahimmanci, kamar bel ɗin zama. Don kwalabe PET, amfani da adadi kaɗan na acid mai cirewa, CHDM, glyhyl din glyhyl (DEG) ko wasu masu ba da shawara na iya zama da amfani: idan kawai aka yi amfani da adadi kaɗan na comonomers, yin saurin kumburi amma ba a hana shi gaba ɗaya. A sakamakon haka, ana iya samun kwalabe ta hanyar budewa busa mold ("SBM"), waxanda suke da haske da kuma lu'ulu'u wanda ya isa ya zama isasshen shinge ga kamshi da ma iskar gas, kamar su carbon dioxide a cikin abubuwan sha mai sha.

Samar

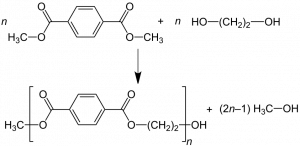

Polyethylene terephthalate an haifeshi daga sinadarin glycol da kuma karafarin rage (C6H4(CO2CH3)2) ko Sankaracic acid.

Tsohon shine a fassarar amsawa, alhali kuwa ƙarshen abu ne esterification dauki.

Tsarin ƙwaƙwalwar ƙwayar cuta

In karafarin rage aiwatarwa, wannan mahaɗin da haɓakar haɓakar ethylene ana amsa su a cikin narkewa a 150-200 ° C tare da a mai samar da kayan masarufi. methanol (CH3OH) an cire ta distillation don fitar da aikin gaba. Wuce gona da iri tare da taimakon wuri. Mataki na biyu na transesterification ya ci gaba a 270-280 ° C, tare da ci gaba da narkewar ethylene glycol kuma.

An daidaita halayen kamar haka:

- Mataki na farko

- C6H4(CO2CH3)2 + 2 KYAUTA2CH2OH → C6H4(CO2CH2CH2OH)2 + 2 CH3OH

- Mataki na biyu

- n C6H4(CO2CH2CH2OH)2 [(CO) C6H4(CO2CH2CH2O)]n + n HADA2CH2OH

Tsarin acid na Terephthalic

a cikin Sankaracic acid aiwatarwa, esterification na ethylene glycol da terephthalic acid ana gudanar da su kai tsaye a matsakaicin matsin lamba (sandar 2.7-5.5) da babban zazzabi (220-260 ° C). Ruwa yana shafewa a cikin aikin, kuma ana ci gaba da cire shi ta hanyar narkewa:

- n C6H4(CO2H)2 + n HADA2CH2OH → [(CO) C6H4(CO2CH2CH2O)]n + 2n H2O

Ragewa

PET yana fuskantar nau'ikan lalata iri iri yayin aiki. Babban lalatattun abubuwa waɗanda zasu iya faruwa sune hydrolytic, kuma tabbas mafi mahimmanci, hadawan abu da iskar shaƙa. Lokacin da PET ta lalata, abubuwa da yawa suna faruwa: discoloration, sarkar almakashi sakamakon shi rage nauyi kwayoyin, samuwar sinadarin acetaldehyde, Da kuma hanyoyin haɗin giciye ("Gel" ko "kifi-ido" samuwar). Rarrabawa ya samo asali ne daga samuwar wasu nau'ikan tsarin chromophoric biyo bayan tsawan magani mai tsafta a tsawan yanayin. Wannan ya zama matsala yayin da bukatun gani na polymer suke da girma sosai, kamar su aikace-aikacen marufi. Lalacewar yanayin zafi da yanayin zafi na haifar da halaye marasa tsari da aikin kayan.

Hanya guda don rage wannan ita ce amfani da a copolymer. Comonomers irin su CHDM ko keɓaɓɓen acid runtse zafin jiki na narkewa da rage ƙimar yawan PET (musamman mahimmanci lokacin da ake amfani da kayan don ƙirar kwalba). Don haka, resin za'a iya zama filastin a ƙananan yanayin zafi da / ko tare da ƙananan ƙarfi. Wannan yana taimakawa wajen hana lalata, rage acetaldehyde abun ciki na samfurin da aka gama zuwa matakin da aka karɓa (shine, ba a sanshi ba). Duba abokan aiki, sama. Wata hanyar inganta zaman lafiyar polymer ita ce amfani da daskararru, galibi maganin antioxidants kamar su phosphites. Kwanan nan, an inganta matakan inganta ƙwayoyin kwayoyin halitta ta amfani da kayan kemikal.

Acetaldehyde

Acetaldehyde abu ne mara launi, mai canzawa tare da ƙanshin 'ya'yan itace. Kodayake yana samuwa ne ta hanyar wasu 'ya'yan itace, amma yana iya haifar da dandano a ruwan kwalba. Acetaldehyde yana haifar da lalacewar PET ta hanyar sarrafa kayan. Babban yanayin zafi (PET ya bazu sama da 300 ° C ko 570 ° F), matsin lamba mai yawa, saurin wuce gona da iri (yawan zubar ruwa yana kara zafin jiki), da kuma lokutan zaman ganga duk suna taimakawa wajen samar da acetaldehyde. Lokacin da ake samar da acetaldehyde, wasu daga ciki suna narkewa a bangon akwati sannan kuma yaxuwa a cikin samfurin da aka adana a ciki, musanya dandano da ƙanshi. Wannan ba matsala irin wannan ga marasa amfani (kamar shamfu), don ruwan 'ya'yan itace (wanda ya riga ya ƙunshi acetaldehyde), ko kuma ga abin sha mai ƙarfi kamar giya mai taushi. Don kwalban ruwa, kodayake, ƙananan abun ciki na acetaldehyde yana da mahimmanci, saboda, idan babu wani abu da ke rufe ƙanshin ƙanshi, har ma da ƙananan kwalliya (sassa 10 na biliyan a cikin ruwa) na acetaldehyde na iya samar da ɗanɗano-ɗanɗano.

Antimony

Antimony (Sb) wani sinadarin ironloid ne wanda ake amfani dashi azaman mai kara kuzari kamar su maganin antimony trioxide (Sb2O3) ko maganin antimony triacetate a cikin samar da PET. Bayan ƙirar, ana iya gano adadin maganin ƙwari a saman samfurin. Ana iya cire wannan ragowar tare da wanka. Antimony shima ya kasance cikin kayan da kansa kuma yana iya, don haka, ƙaura zuwa cikin abinci da abin sha. Fitar da PET zuwa tafasa ko microwaving na iya haɓaka matakan antimony sosai, watakila sama da matakan gurɓataccen matakin USEPA. Iyakar ruwan sha da WHO ta tantance kashi 20 ne a cikin biliyan daya (WHO, 2003), kuma iyakancin ruwan sha a Amurka yakai kashi 6 cikin biliyan daya. Kodayake antioxide trioxide yana da ƙananan guba lokacin da aka sha shi da baki, kasancewar har yanzu abin damuwa ne. Switzerland Ofishin Tarayya na Kiwon Lafiyar Jama'a yayi bincike kan yawan ƙaurawar maganin rigakafi, kwatanta ruwan kwalba a cikin PET da gilashi: antwayar ruwan antimony a cikin kwalaben PET sun fi girma, amma har yanzu suna ƙasa da ƙimar da aka yarda sosai. Ofishin Kula da Kiwon Lafiyar Jama'a na Switzerland ya kammala cewa kananan kwayoyi na yin kaura daga PET zuwa cikin ruwan kwalba, amma matsalar lafiyar da ke haifar da karancin abubuwan da aka samu ba abin kulawa bane (1% na "Abin haƙuri a kowace rana”Ƙaddara ta WHO). Daga baya (2006) amma binciken da aka yada sosai ya sami adadin antimony a cikin ruwa a cikin kwalaben PET. Hukumar ta WHO ta wallafa kimanta hadari don cutar antimon a cikin ruwan sha.

Ruwan ruwan 'ya'yan itace sun fi mai da hankali (wanda ba a kafa jagororinsu ba), duk da haka, waɗanda aka samar da su a kwalba a cikin PET a cikin Burtaniya an gano cewa sun ƙunshi har zuwa 44.7 µg / L na maganin rigakafi, sama da iyakar EU tap ruwa na 5 µg / L.

Halittuwar halitta

nocardia na iya lalata PET tare da enzyme na esterase.

Masana kimiyyar Jafananci sun ware kwayoyin Ideonella sakaiensis wanda ya mallaki enzymes guda biyu waɗanda zasu iya rushe PET cikin ƙananan ƙananan abubuwa waɗanda ƙwayoyin cuta zasu iya narkewa. Wani mulkin mallaka na I. sakai zai iya watsar da fim ɗin filastik a cikin makonni shida.

Safety

Sharhin da aka buga a Harkokin Kiwon Lafiya na Muhalli a watan Afrilun 2010 ya ba da shawarar cewa PET na iya samarwa masu rushewar endocrine a karkashin yanayin amfani na kowa da shawarar bincike akan wannan batun. Hanyoyin da aka gabatar dasu sun hada da koyawa na phthalates kazalika da koyarwa na maganin sanyi. Rubutun da aka buga a Jaridar Kula da Mahalli a watan Afrilun 2012 ya ƙare cewa maida hankali a ciki deionized ruwa aka ajiye su a cikin kwalaben PET suna cikin iyakar yarda da EU ko da an adana su a taƙaice a yanayin zafi har zuwa 60 ° C (140 ° F), yayin da abubuwan da ke cikin kwalba (ruwa ko abin sha mai laushi) wani lokaci na iya wuce iyakar EU bayan ƙasa da shekara ɗaya ta ajiya a ɗaki zafin jiki

Kayan aiki na kwalban kwalba

Akwai hanyoyi guda biyu na yin gyaran gashi ga kwalabe PET, mataki-mataki da mataki biyu. A cikin gyara matakai biyu, ana amfani da injin din daban. Maganin injin farko na injin yana yin tsari, wanda yayi kama da bututun gwaji, tare da zaren kwalban kwal da aka riga aka hada su. Jikin bututu ya yi kauri sosai, kamar yadda za a harba shi zuwa kamannin sa na karshe a mataki na biyu da ake amfani da shi budewa busa mold.

A mataki na biyu, ana yin amfani da preforms cikin hanzari sannan kuma a sanya karuwa a kan wani sashi na bangarorin biyu don samar da su zuwa kamannin karshe na kwalbar. Hakanan ana amfani dasu na yau da kullun (kwalayen da ba a cika dasu ba) azaman ababen amfani da kwantena na musamman; ban da baƙon alewa, wasu surori na Red Cross suna rarraba su a matsayin wani ɓangare na shirin Vial of Life ga masu gida don adana tarihin likita don masu amsawa na gaggawa. Wani amfani da mutane gama gari ke amfani da su don kayan ganyayyaki sune kwantena a cikin aikin waje.

A cikin injuna guda-mataki, ana aiwatar da tsari gaba daya daga kayan masarufi zuwa ganga daya a cikin injin daya, yana sanya shi dacewa musamman don gyaran siffofi marasa daidaituwa (gyaran masana'anta), gami da kwalba, kayan kwalliyar filaye, fasikan flask da sauransu Babban amfanin sa shine raguwa sararin samaniya, sarrafa kaya da makamashi, kuma mafi girman ingancin gani sama da yadda ake aiwatar da matakan biyu.

Masana'antar ta hanyar Polyester

A shekara ta 2016, an kiyasta cewa ana samar da tan miliyan 56 na PET a kowace shekara.

Yayinda yawancin thermoplastics zasu iya, a akasi, a sake sarrafa su, PET sake amfani da kwalban yana da amfani sosai fiye da sauran aikace-aikacen filastik saboda girman darajar guduro da kusan amfani da PET don ruwa mai amfani da kwalba da kwalba mai laushi. PET yana da guduro lambar tantancewa na 1. Abubuwan da Firayim ke amfani dasu don sake amfani da PET sune polyester fiber, ɗauri, da kwantena marasa abinci.

Saboda sake amfani da PET da dangi mai yawa na bayan sharar gida a cikin nau'ikan kwalabe, PET tana samun kasuwa cikin hanzari a matsayin abin magana na kafet. Masana'antu Mohawk An sake fitarwa a cikin 1999, an sake amfani da abun cikin 100% na kayan aikin PET fiber. Tun daga wannan lokacin, sama da kwalabe biliyan 17 da aka sake yin amfani da su cikin firam. Pharr Yarns, mai siyarwa ga masana'antun kera masu yawa da suka hada da Looptex, Dobbs Mills, da Berkshire Flooring, samar da BCF (mafi yawa ci gaba filament) PET kifin katako mai dauke da mafi ƙarancin 25% bayan bayanan mai amfani da aka sake amfani dashi.

PET, kamar yadda yake da filastik masu yawa, shima kyakkyawan ɗan takara ne don zubar da zafin (fitina), kamar yadda aka hada da carbon, hydrogen, da oxygen, tare da kawai gano adadin abubuwan da zasu kara kuzari (amma ba bu sulfur). PET yana da wadatar abun ciki na kwal mai taushi.

Lokacin sake yin polyethylene terephthalate ko PET ko polyester, gaba ɗaya hanyoyi biyu dole ne a bambance su:

- Tsarin sarrafa sinadaran ya koma asalin abubuwanda aka yiwa kayayyakin aikin tsarkakakke Sankaracic acid (PTA) ko karafarin rage (DMT) da sinadarin glycol (EG) inda polymer aka lalata gaba ɗaya, ko kuma a cikin tsari tsaka-tsaki kamar bis (2-hydroxyethyl) terefta

- Yin amfani da injin sake amfani dashi inda ake kula da abubuwan asalin aikin polymer ko sake tsarin su.

Yin gyaran kemikal na PET zai zama mai tsada tsada kawai amfani da layin sake amfani da ƙarfi fiye da tan 50,000 / shekara. Za'a iya ganin irin waɗannan layin, idan gaba ɗaya, a cikin wuraren samarwa na manyan masana'antar polyester. Yunkuri da yawa na girman masana'antu don kafa irin wannan tsire-tsire masu sake sarrafa ma'amala a da amma ba tare da samun nasara ba. Hatta sake yin amfani da sinadarai a ƙasar ta Japan bai zama wani ci gaba na masana'antu ba. Dalilai biyu na wannan sune: a farko, wahalar daidaito da cigaba da kwalaben sharar gida mai dumbin yawa a wannan shafi daya, kuma, a na biyu, yawan hauhawar farashin da kwalaben kwalabe suke karba. Farashin kwalaben kwalabe ya ninka misali tsakanin shekarun 2000 da 2008 daga kimanin Euro 50 / ton zuwa sama da Euro / ton a shekara ta 500.

Yin amfani da injin sarrafawa ko yaduwa da PET kai tsaye a cikin jihar polymeric ana gudanar dashi a yawancin bambance bambancen yau. Wadannan nau'ikan tafiyar matakai ne na masana'antu da ƙanana da matsakaitan masana'antu. Zai iya wadatar da wadatar tsada tare da damar shuka a cikin adadin tan 5000 - 20,000 / shekara. A wannan yanayin, kusan dukkanin nau'ikan sake-kayan da aka sake amfani dasu cikin zagayawa kayan duniya suna yiwuwa a yau. Ana tattauna waɗannan ra'ayoyin sake amfani da abubuwa na zamani dalla-dalla.

Bayan gurɓatattun sunadarai da ragewa samfuran da aka haifar yayin aiki na farko da amfani, raunin injiniyoyi suna wakiltar babban ɓangaren ingancin ƙazantar ƙazanta ƙazaman ruwa. Kayayyakin da aka sabunta su ana ƙara shigo da su ta tsarin masana'antu, waɗanda asalinsu don sabbin kayan kawai. Sabili da haka, rarrabe rarrabewa, rabuwa da tsabtatawa hanyoyin zama mafi mahimmanci don ingantaccen polyester mai inganci.

Lokacin da muke magana game da masana'antar sake sarrafa polyester, muna mai da hankali ne kan sake yin amfani da kwalaban PET, waɗanda ake amfani da ita don kowane nau'in kayan saka ruwa kamar ruwa, abubuwan sha mai cike da abubuwan sha, ruwan giya, giya, sabulu, sabulu, sinadarai na gida da sauransu. Kwalabe suna da sauƙin rarrabewa saboda siffofi da daidaito da rarrabe daga rafukan filastik sharar gida ko dai ta atomatik ko kuma ta hanyar sarrafa abubuwa. Kafaffen masana'antar polyester da aka ƙera ya ƙunshi manyan sassan uku:

- Tarin tarin kwalabar PET da sharar gida: Lalacewar sharar gida

- Production na tsabta kwalban flakes: flake samar

- Canza kaya na PET zuwa kayan ƙarshe: aiki na flake

Samfurin matsakaici daga sashin farko shine ƙaddamar da ƙarancin kwalban tare da abun PET wanda yafi 90%. Mafi yawan nau'in ciniki na yau da kullun shine bale amma kuma an yi birgima ko ma sako-sako, kwalabe da aka yanke yankan sun zama ruwan dare a kasuwa. A sashi na biyu, kwalayen da aka tara suna canzawa don tsabtace kwalban PET. Wannan mataki na iya zama mafi girma ko complexasa da wahala da rikitarwa dangane da buƙata ingancin flake na ƙarshe. A yayin mataki na uku, ana sarrafa fulawar kwalban PET ga kowane irin kayayyaki kamar fim, kwalabe, fiber, filati, madaidaici ko matsakaici kamar pellets don cigaba da aiki da robobi.

Bayan wannan sakerren kayan polyester na waje (bayan-mai amfani), lambobin hanyoyin sake gini na ciki (wanda ya fara amfani da su) sun wanzu, inda baturen polymer da yake lalacewa baya fita daga rukunin samarwa zuwa kasuwanninda yake kyauta, kuma a sake amfani dashi a da'irar samarwa iri daya. Ta wannan hanyar, ana sake amfani da sharar fiber kai tsaye don samar da fiber, an sake amfani da sharar gida kai tsaye don samar da preforms, kuma ana sake amfani da sharar fim kai tsaye don fitar da fim.

PET sake amfani da kwalban

Tsarkakewa da lalata

Nasarar kowace ma'ana ta sakewa tana ɓoye cikin ingantaccen tsarkakewa da lalata a daidai wurin yayin aiki kuma zuwa gwargwadon buƙata ko ake so.

Gabaɗaya, waɗannan masu amfani ana amfani da su: An cire farkon abubuwan da ake sarrafa abubuwa na ƙasashen waje, kuma yayin da ake yin wannan sosai, yadda ingantaccen tsari yake.

Babban Filastik zafin jiki na PET a cikin kewayon 280 ° C (536 ° F) shine dalilin da ya sa kusan dukkanin ƙazantar ƙazantar ƙazantar abubuwa kamar PVC, PLAN, polyolefin, chemicalan itace mai daskarewa da fiber takarda, polyvinyl acetate, narke mai narkewa, wakilai masu launi, sukari, da furotin ragowar suna canzawa zuwa samfura masu lalacewa masu launi waɗanda, a nasu biyun, na iya sakin ƙari da kayayyakin lalata abubuwa. Bayan haka, yawan lahani a cikin sarkar polymer yana ƙaruwa sosai. Girman kwayar zarra na ƙazanta yana da faɗi sosai, manyan ƙwayoyin 60-1000 µm-waɗanda ake iya gani da ido tsirara kuma masu sauƙin tacewa-suna wakiltar ƙaramar mugunta, tunda gabadayan fuskokinsu ba su da yawa kuma saurin lalacewa ya zama ƙasa. Tasirin ƙananan ƙwayoyin cuta, wanda –saboda suna da yawa- ƙara yawan lahani a cikin polymer, ya fi girma.

Taken “Abin da ido baya gani zuciya ba zai iya yin baƙin ciki ba” ana ɗaukarsa da mahimmanci a cikin ayyukan sake sarrafawa da yawa. Sabili da haka, banda rarrabuwa mai inganci, cire abubuwa masu ƙazanta na bayyane ta hanyar narkewar matakan tace wani bangare a wannan yanayin.

Gabaɗaya, mutum na iya cewa hanyoyin da ake bi don yin flakes ɗin kwalban PET daga kwalaben da aka tara suna da yawa kamar yadda rafuka daban-daban na sharar sun bambanta da yanayin su da ingancin su. Dangane da fasaha babu wata hanya guda daya da za'ayi. A halin yanzu, akwai kamfanonin injiniyoyi da yawa waɗanda ke ba da tsire-tsire da kayan haɗin flake, kuma yana da wuya a yanke shawara don ƙirar ɗaya ko wasu ƙirar tsire-tsire. Koyaya, akwai matakai waɗanda suke raba mafi yawan waɗannan ƙa'idodin. Dogaro da abun da aka shigar dashi da kuma ƙazantaccen kayan shigar dashi, ana amfani da matakan aiwatarwa gaba ɗaya.

- Budewar Bale, budewar bidi'a

- Zaɓin tsari da zaɓi don launuka daban-daban, kayan aikin polima na waje musamman PVC, batun ƙasashen waje, cire fim, takarda, gilashi, yashi, ƙasa, duwatsu, da ƙarfe

- Wankewa ba tare da yankan ba

- M yankan bushe ko kuma hade zuwa pre-wanke

- Cire duwatsun, gilashi, da ƙarfe

- Siaukar iska don cire fim, takarda, da alamun rubutu

- Nika, bushe da / ko rigar

- Cire ƙananan polymers na ƙarancin girma (kofuna waɗanda) ta bambance-bambancen yawa

- Wanke-zafi

- Caustic wanka, da kuma gogewar farfajiya, da kekantaccen danko da lalata

- Rinsing

- Tsabtace ruwa mai tsabta

- Bushewa

- Isar iska

- Ana saita flake ta atomatik

- Da'irar ruwa da fasahar kulawa da ruwa

- Gudun ingancin flake

Lalacewa da lahani na kayan

Yawan lalatattun abubuwa da lahani da ke tattare da kayan polymeric suna ƙaruwa har abada — lokacin aiki da kuma lokacin amfani da polymer — yin la'akari da rayuwar sabis na haɓaka, haɓaka aikace-aikacen ƙarshe da maimaita sake amfani. Game da kwalban PET da aka sake yin amfani da su, lahanin da aka ambata ana iya rarrabe su cikin rukunoni masu zuwa:

- Politister na OH- ko ƙungiyoyin COOH-end an canza su zuwa rukunin mutu-mutu ko marasa aiki, misali samuwar vinyl ester ƙarshen ƙungiyoyi ta hanyar rashin ruwa ko yanke hukunci na ɓarkewar acid, amsawar OH-ko COOH- ƙarshen ƙungiyoyi tare da rugujewar ayyuka na ayyuka samfura kamar mono-carbonic acid ko giya. Sakamakon raguwa ne sake kunnawa yayin sake-sakewa ko sake SSP da fadada nauyin kwayoyin.

- Grouparshen ƙimar grouparshe ya motsa zuwa jagorancin OOungiyoyin COOH ƙarshen da aka gina ta hanyar lalata yanayin zafi da iskar shaka. Sakamakon yana raguwa a cikin aiki, da haɓaka cikin lalata acid na autocatalytic yayin jiyya na zafi a gaban zafi.

- Yawan ƙwayoyin macromolecules yana ƙaruwa. Rarraba gel da lahani mai kyau.

- Lamba, taro, da nau'ikan abubuwa marasa daidaituwa na halitta da na cikin gida na haɓaka. Tare da kowane sabon tashin hankali na thermal, abubuwa na kasashen waje zasu amsa ta hanyar lalata. Wannan yana haifar da 'yanci na ƙarin lalata lalata abubuwa masu goyan baya da abubuwan canza launi.

- Hungiyoyin Hydroxide da peroxide suna haɓaka a saman samfuran samfuran da aka yi da polyester a gaban iska (oxygen) da laima. Wannan tsari yana haɓaka da hasken ultraviolet. A yayin aikin jijiyoyin jiki, peroxides na ruwa tushen tushe ne da ke haifar da iskar oxygen, wadanda sune tushen lalatawar iskar gas. Rushe da peroxides na ruwa shine ya faru kafin magani na farko ko lokacin plasticization kuma ana iya tallafa masa ta hanyar abubuwan da suka dace kamar su maganin antioxidants.

Tare da yin la’akari da lahani da ƙarancin sunadarai da aka ambata a sama, akwai ci gaba mai canzawa halaye na abubuwan haɓaka na polymer a yayin kowane tsarin sake sarrafawa, wanda bincike-bincike na dakin gwaje-gwaje da na zahiri ke gano su.

A musamman:

- Aseara yawan kungiyoyin COOH

- Numberara yawan launuka b

- Ofarin haze (m samfurori)

- Ofara yawan abubuwan oligomer

- Ragewa a cikin tacewa

- Ofara abun ciki na samfuran samfuri kamar su acetaldehyde, formaldehyde

- Ara yawan gurɓatattun ƙasashen waje

- Ragewa cikin launi L

- Rage na danko na ciki ko tsayayyar danko

- Rage yawan zafin jiki na gushewa da karuwa da saurin kuzari

- Rage kayan injiniyan kamar ƙarfin ƙarfin ƙarfe, elongation a break or na roba modulus

- Watsa shirye-shiryen rarraba nauyin kwayoyin

Sake yin amfani da kwalabe-kwalaben PET har ila yau tsari ne na masana'antu wanda kamfanoni injiniyan injiniya da yawa suka bayar.

Gudun misalai don polyester da aka sake sabuntawa

Tsarin sake sarrafawa tare da polyester kusan sun bambanta kamar yadda masana'antun masana'antu suka dogara da ƙwayoyin farko ko narkewa. Dogaro da tsabtan abubuwan da aka sake yin fa'ida, ana iya amfani da polyester a yau a mafi yawan ayyukan masana'antar polyester kamar haɗuwa da budurwa polymer ko ƙarawa kamar 100% polymer da aka sake yin fa'ida. Wasu keɓaɓɓu kamar BOPET-fim na ƙananan kauri, aikace-aikace na musamman kamar fim na gani ko yadudduka ta hanyar jujjuyawar FDY a> 6000 m / min, microfilaments, da micro-fibers ana samar dasu ne daga budurwa polyester kawai.

Sauƙaƙar sake-pelletizing na flakes kwalban

Wannan tsari ya ƙunshi canza sharar kwalba zuwa flakes, ta bushewa da kuma kuka da flakes, ta plasticizing da tacewa, da ta pelletizing. Samfurin sigar amorphous sake-mai-girma na wani ɗanɗano mai girman gaske a cikin kewayon 0.55-0.7 dℓ / g, gwargwadon yadda aka gama bushe-bushe na alamun PET.

Musamman fasalin sune: Acetaldehyde da oligomers suna ƙunshe a cikin pellets a ƙananan matakin; danko an rage shi ko ta yaya, pellets are amorphous kuma ya zama dole ne a rude shi kuma a bushe kafin a cigaba da aiki.

Aika zuwa:

- A-PET fim don zazzana

- Toari ga samarwar budurwa PET

- BoPET shirya fim

- Kwalban PET resin ta SSP

- Yankin yatsa

- Filastin injiniya

- Filaye

- Ba a saka ba

- Shirya ratsi

- Beratuwar fiber.

Zaɓi hanyar sake-pelletizing hanya yana nufin samun ƙarin tsari na juyawa wanda shine, a gefe ɗaya, makamashi mai tsada da ƙimar farashi, yana haifar da lalata zafi. A daya gefen, pelletizing mataki yana samar da wadannan ab advantagesbuwan amfãni:

- M narke mai tsananin gaske

- Matsakaici ingancin iko

- Gyara ta hanyar ƙari

- Zaɓin samfurin da rabuwa da inganci

- Gudanar da sassauci yana ƙaruwa

- Ingancin Uniformization.

Ureirƙirar PET-pellets ko flakes na kwalabe (kwalba zuwa kwalba) da A-PET

Wannan tsari, a ka'ida, yayi kama da wanda aka bayyana a sama; duk da haka, pellets ɗin da aka samar ana yin su ne kai tsaye (ci gaba ko kuma a daina aiki) an yi su da haske sannan kuma an sanya su cikin kwaskwarimar polycondensation (SSP) a cikin bushewar bushewa ko maɓallin bututun da ke tsaye. A lokacin wannan matakin sarrafawar, an sake sake gina ainihin abin da ke cikin 0.80-0.085 dℓ / g kuma, a lokaci guda, an rage abun acetaldehyde zuwa <1 ppm.

Gaskiyar cewa wasu masana'antun injiniya da masu ginin layi a Turai da Amurka suna ƙoƙari don ba da tsarin sake sarrafawa mai zaman kanta, misali abin da ake kira kwalban-kwalban (B-2-B), kamar su BATSA, Starringer, URRC ko BÜHLER, yana da nufin samar da hujja game da "wanzuwar" ragowar abubuwan da ake buƙata na cirewa da kuma cire abin gurɓata samfura bisa ga FDA da ke amfani da gwajin da ake kira ƙalubale, wanda ya zama dole don aikace-aikacen polyester ɗin da aka kula a cikin bangaren abinci. Bayan wannan yardawar tsari ya zama dole duk wani mai amfani da irin wannan tsari ya kasance yana duba iyakokin FDA koyaushe don kayayyakin da shi kansa ya ƙera don aikinsa.

Canjin kai tsaye na kwalbar flakes

Don adana farashi, adadin masu samar da tsaka-tsaki na polyester kamar su dunƙule, murƙun ƙyallen, ko kuma masana'antar fim an yi aiki da kai tsaye ta amfani da PET-flakes, daga lura da kwalaben da aka yi amfani da su, tare da nufin keɓar da ƙaruwa. yawan polyester tsaka-tsaki. Don daidaituwa na danko mai mahimmanci, banda ingantaccen bushewa na flakes, yana iya yiwuwa ma ya sake haifar da danko ta hanyar polycondensation a cikin narke lokaci ko m-jihar polycondensation na flakes. Sabbin hanyoyin PET flake na sauya fasalin suna amfani da tagwayen dabaran murkushewa, masu amfani da sikirin da yawa ko tsarin juyawa da kuma yanayin daidaituwa don cire danshi da kuma guje wa bushewar pre-bushewa. Wadannan hanyoyin suna bada damar jujjuyawar wutan lantarki PET ba tare da rage girman danko ba sakamakon hydrolysis.

Game da amfani da tulin kwalban PET, babban sashi na kusan kashi 70% an canza shi zuwa zaruruwa da filara. Lokacin amfani da kayan sakandare kai tsaye kamar su kwalban flakes a cikin hanyoyin juya, akwai principlesan ka'idojin aiki don samu.

Matakan sikeli masu sauri-sauri don kera POY a kullum suna bukatar danko na 0.62-0.64 dℓ / g. Farawa daga flakes na kwalba, ana iya saita danko ta hanyar matakin bushewa. Additionalarin amfani da TiO2 ya zama dole don cikakke yarn ko kuma mara ma'ana. Don kare ruwan inabin, ingantaccen tacewar narkewa yake, a kowane hali ya zama dole. Don lokacin, adadin POY da aka yi daga 100% sake amfani da polyester ya ƙanƙane saboda wannan tsari yana buƙatar tsarkin mai narkewa mai narkewa. Mafi yawan lokaci, ana amfani da cakuda budurwa da kuma rubabbun pellets.

Bersatuwar fiber suna gudana cikin kewayon ɗanɗano na ciki wanda ya ta'allaka ƙanƙantar da kaɗan kuma hakan yakamata ya kasance tsakanin 0.58 da 0.62 dℓ / g. A wannan yanayin, kuma, za a iya gyara danko da ake buƙata ta hanyar bushewa ko daidaitawar yanayi idan ana fitar da kuda. Don daidaitawar danko, duk da haka, ƙari ne mai daidaita sarkar tsawon saiti kamar sinadarin glycol or glyhyl din glyhyl Hakanan za'a iya amfani dashi.

Spinning ba saka-a filin mai kyau don aikace-aikacen sutura da kuma kayan yaji mara nauyi kamar kayan yau da kullun, misali don rufin rufin ko a ginin hanya — ana iya samara da su ta fuskokin kwalba. Dangane da yanayin walƙatarwa ya sake kasancewa tsakanin kewayon 0.58-0.65 d / g.

Fieldaya daga cikin filin don ƙara sha'awar inda ake amfani da kayan da aka sake amfani dashi shine ƙirƙirar rarar kayan ƙara ƙarfi, da keɓaɓɓu. A cikin halayen guda biyu, kayan farawa kayan yau da kullun kayan sakewa ne na zurfin ɗanɗuwa ciki. Babban masana'anta na daskararrun abubuwa kamar yadda yakamata kuma an kirkire su da tsinke.

Sake sarrafawa da dodanni

Polyethylene terephthalate za a iya zazzage shi don samar da masu monomers na yanki. Bayan tsarkakewa, ana iya amfani da monomers don shirya sabon polyethylene terephthalate. Za'a iya rufe ɗayan ester a cikin polyethylene terephthalate ta hanyar hydrolysis, ko ta transesterification. Abubuwan da za a bi su ne kawai juyawa daga waɗanda aka yi amfani da su a cikin samarwa.

M glycolysis

Wani bangare na glycolysis (transesterification tare da ethylene glycol) yana canza jigon polymer zuwa gajere masu ɗaure ciki na ado wanda za'a iya narkewa a ƙarancin zafin jiki. Da zarar an sami 'yanci, to ana iya ciyar da oligomers a cikin tsarin samar da kayan aikin don samar da kwayoyin halitta.

Aikin ya ƙunshi a cikin ciyar da ƙwayar kwalba na 10-25% yayin riƙe ingantaccen ƙwayar kwalban da aka ƙera ta kan layi. An warware wannan manufar ta hanyar lalata ƙananan kwalabe na PET-tuni yayin plasticization na farko, wanda za'a iya aiwatar da shi ta fuskoki guda-ko a maɓallin dunƙule-fuskoki daban-daban zuwa kusan 0.30 dℓ / g ta ƙara ƙananan adadi na ethylene glycol da ta hanyar gurguntar da kwarin gwiwar narkewar ruwa zuwa ingantaccen tacewa kai tsaye bayan plasticization. Bugu da ƙari, an kawo zazzabi zuwa mafi ƙarancin yiwuwar iyaka. Bugu da ƙari, tare da wannan hanyar sarrafawa, yiwuwar gurɓataccen sunadarai na peroxides na mai yiwuwa ta hanyar ƙara P-kwantar da hankali kai tsaye lokacin plasticizing. Rushewar rukunin peroxide na ruwa shine, tare da sauran hanyoyin, an riga an aiwatar da su a ƙarshen matakin karshe na maganin flake misali ta ƙara H3PO3. Abubuwan da aka sake yin amfani da glycolyzed kuma an tace su an sake sarrafa su ana ci gaba da ciyar dasu zuwa esterification ko prepolycondensation reactor, ana yin amfani da dosing yawa na albarkatun kasa dai-dai.

Jimlar glycolysis, methanolysis, da hydrolysis

Kulawa da datti na polyester ta hanyar glycolysis gaba daya don canza polyester gaba daya bis (2-hydroxyethyl) terefta (C6H4(CO2CH2CH2OH)2). Wannan fili yana tsarkaka ta hanyar injin tururuwa, kuma yana daya daga tsaka-tsakin da ake amfani da shi wajen kera polyester. Hankalin da ya kunsa shine kamar haka:

- [(CO) C6H4(CO2CH2CH2O)]n + n HADA2CH2OH → n C6H4(CO2CH2CH2OH)2

An aiwatar da wannan hanyar girke-girke a kan sikelin masana'antu a Japan kamar gwajin gwaji.

Mai kama da duka glycolysis, methanolysis yana canza polyester zuwa karafarin rage, wanda za'a iya tace kuma injin distilled:

- [(CO) C6H4(CO2CH2CH2O)]n + 2n CH3OH → n C6H4(CO2CH3)2

Ba a daɗewa a masana'antar methanolysis saboda masana'antar polyester dangane da dimethyl terephthalate ya durƙushe sosai, kuma yawancin masu samar da ƙwaƙwalwar dimethyl sun ɓace.

Hakanan kamar yadda yake a sama, polyethylene terephthalate za a iya hydrolyzed zuwa terephthalic acid da sinadarin glycol a karkashin zafin jiki da matsin lamba. Sakamakon acid na ɗanda zai iya tsarkake ta maimaitawa don samar da abu wanda ya dace da sake kewaya:

- [(CO) C6H4(CO2CH2CH2O)]n + 2n H2Ya → n C6H4(CO2H)2 + n HADA2CH2OH

Wannan hanyar ba ta bayyana an yi kasuwanci ba tukuna.